Home » Products » Elemental Analysis » NEX LS In-Line Coating Analyzer

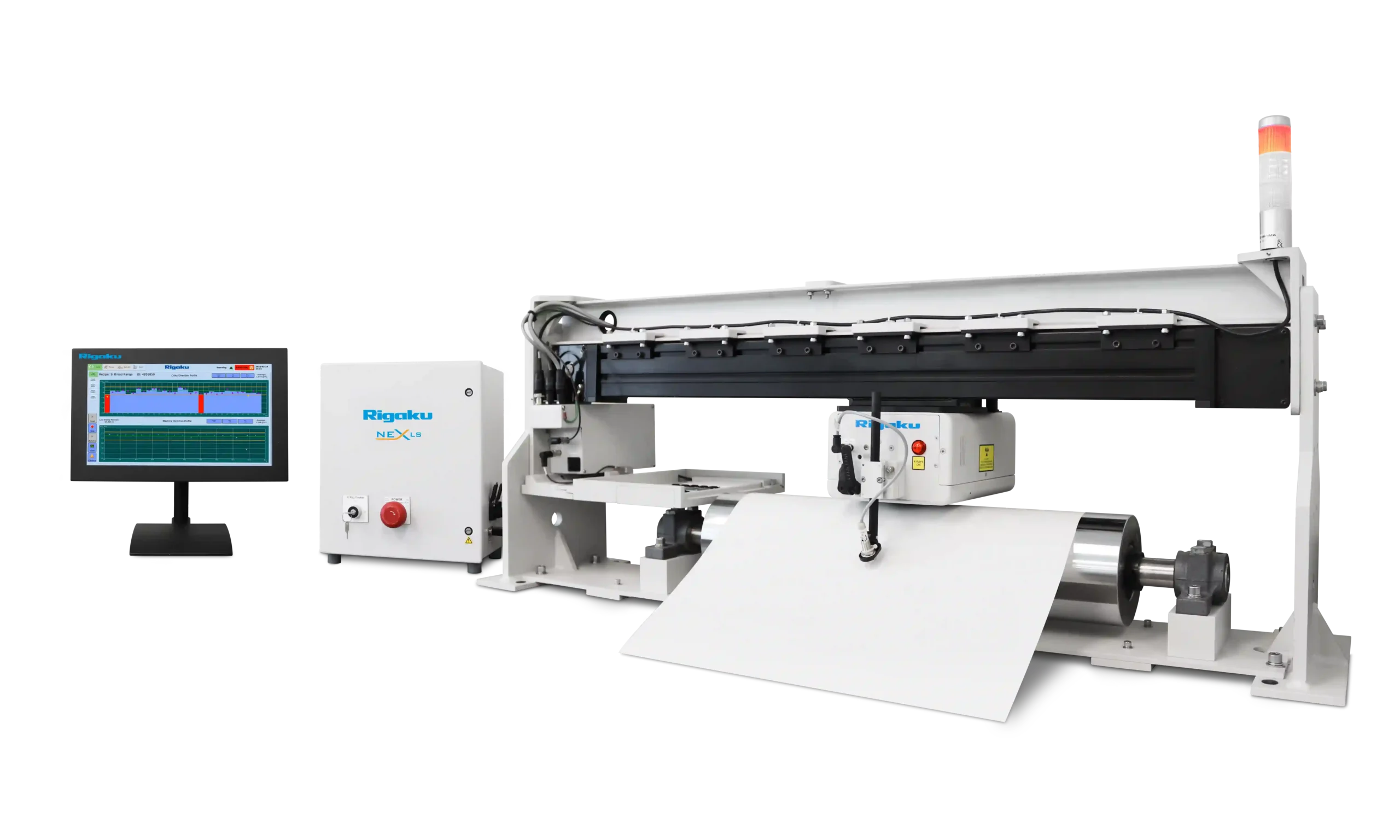

NEX LS In-Line Coating Analyzer

The NEX LS In-Line Coating Analyzer is an advanced in-line coating analyzer for real-time multi-element analysis and quality control by Rigaku Solutions.

Product Overview

The NEX LS from Rigaku Solutions is a cutting-edge in-line coating analyzer designed for real-time multi-element analysis.

Utilising advanced EDXRF technology, it provides accurate and reliable measurements of coating thickness and elemental composition in roll-to-roll applications.

The system features a scanning analytical head for cross-direction and machine-direction profiling, an industrial touchscreen interface for ease of use, and automatic calibration for continuous process monitoring.

Ideal for ensuring quality control in various industrial settings, the NEX LS delivers precise and efficient performance, making it an essential tool for optimising production processes.

Features & Benefits

In-Line Coating Analyzer

Multi-Element Analysis

Real-Time Coating Analysis

Key applications

- In-Line Coating Analyzer: Advanced system for real-time coating analysis.

- Multi-Element Analysis: Simultaneously measures multiple elements.

- EDXRF System: Utilises energy dispersive X-ray fluorescence technology.

- Real-Time Coating Analysis: Provides instant measurement results.

- Roll-to-Roll Applications: Ideal for continuous production lines.

- Quality Control Coating Thickness: Ensures precise coating thickness measurements.

- Elemental Composition Measurement: Accurately measures elemental composition.

- Scanning Analytical Head: Enables cross-direction and machine-direction profiling.

- Cross-Direction Profiling: Analyzes coating uniformity across the web.

- Machine-Direction Profiling: Monitors coating consistency along the web.

- Industrial Touchscreen Interface: User-friendly interface for easy operation.

- Automatic Calibration: Simplifies setup and ensures ongoing accuracy.

- Continuous Process Monitoring: Provides uninterrupted analysis during production.

- Rigaku Solutions: Trusted provider of advanced analytical instruments.

NEX LS In-Line Coating Analyzer Product Video

About the NEX LS In-Line Coating Analyzer

The NEX LS by Rigaku Solutions is an advanced in-line coating analyzer designed to meet the rigorous demands of modern industrial production processes. Accurate and reliable coating analysis is essential for maintaining product quality and optimising manufacturing efficiency. The NEX LS addresses these needs with its state-of-the-art EDXRF system, providing real-time multi-element analysis and precise measurements of coating thickness and elemental composition.

In industrial settings, ensuring the uniformity and consistency of coatings is critical. The NEX LS excels in this area with its scanning analytical head, which performs cross-direction and machine-direction profiling. This capability allows manufacturers to monitor coating uniformity across the web and ensure consistent quality along the production line. The system’s high accuracy mass measurement and rapid temperature cycling further enhance its performance, making it suitable for a wide range of applications, including metallic and ceramic materials testing, aeronautics, space industry materials, and energy production.

One of the standout features of the NEX LS is its industrial touchscreen interface, which provides a user-friendly platform for controlling the system and accessing real-time data. The intuitive design simplifies operation, reducing the learning curve and allowing operators to focus on maintaining production quality. Additionally, the system’s automatic calibration ensures ongoing accuracy, eliminating the need for manual adjustments and minimising downtime.

The NEX LS is particularly well-suited for roll-to-roll applications, where continuous monitoring is essential for maintaining production efficiency and quality control. Its ability to perform real-time coating analysis and continuous process monitoring makes it an invaluable tool for industries such as automotive, aerospace, electronics, and packaging. By providing instant feedback on coating thickness and elemental composition, the NEX LS enables manufacturers to make informed adjustments in real-time, ensuring optimal product quality and reducing waste.

The reliability and precision of the NEX LS are backed by Rigaku Solutions’ reputation for excellence in analytical instrumentation. With decades of experience in developing advanced analytical systems, Rigaku Solutions offers a comprehensive solution for coating analysis that meets the highest standards of performance and reliability.

In summary, the NEX LS by Rigaku Solutions is a high-performance in-line coating analyzer designed to deliver accurate and reliable real-time multi-element analysis. Its advanced features, user-friendly interface, and robust design make it an essential tool for ensuring quality control in industrial production processes. Whether for metallic and ceramic materials testing, aeronautics, space industry materials, or energy production, the NEX LS provides the precision and reliability needed to optimise manufacturing efficiency and maintain product quality.

Specifications

| Technique | In-line energy dispersive X-ray fluorescence (EDXRF) | |

|---|---|---|

| Benefit | Helps maintain routine quality control for web and coil applications; in-line EDXRF for determining coating thicknesses or coat weight, or the elemental composition of a product | |

| Technology | Process EDXRF using a scanning analytical head featuring proven NEX Series optical kernel | |

| Attributes | 50 kV 4 W X-ray tube (limited to 5 kV for specific applications), SDD, analyze Al to U, home station with 5-position calibration plate, industrial widescreen touchscreen display with intuitive user interface and flow bar method builder, full scanning or user-defined positions, roll reports, CSV or PDF file logging to USB or a network using industry-standard communications protocols | |

| Power requirements | 100 – 240 V, 5.5 – 10 A (50/60 Hz), dedicated supply | |

| Warranty | 2 years | |

"The Rigaku NEX LS is an in-line EDXRF analyser for real-time, multi-element

coating and thickness measurement in roll-to-roll manufacturing."

Product FAQ's

The NEX LS can analyze a wide range of coatings, including metallic and ceramic materials, ensuring precise measurements of coating thickness and elemental composition.

The scanning analytical head performs cross-direction and machine-direction profiling, allowing for real-time monitoring of coating uniformity and consistency across the web.

Yes, the NEX LS is designed for continuous process monitoring, providing uninterrupted real-time analysis during production runs.

The industrial touchscreen interface provides a user-friendly platform for easy operation and access to real-time data, simplifying the control and monitoring process.

Automatic calibration ensures ongoing accuracy and reliability, reducing the need for manual adjustments and minimising operational downtime.

Applications

Application Note 1

Application Note 2

Application Note 3

Contact Us Today

We take great pleasure in assisting you and ensuring you get a prompt response to your questions

Live chat opening hours Mon – Fri 9:15 to 16:30 (UK Time)